| Issue 8 |

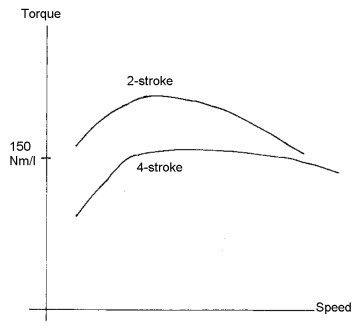

Richard is with Ricardos at Shoreham and the work described had been undertaken as the result of the now widespread desire to reduce CO2 emissions. One way to do this in a motor vehicle is to use a smaller engine operating nearer to full load under normal cruise conditions. It may then have inadequate full-load torque for acceleration or hill-climbing, but this could perhaps be remedied if the engine could switch from a four-stroke to a two-stroke cycle when high torque was required. For example, a six-cylinder engine would then have six power strokes per revolution instead of three. The likely torque/speed curves of such an engine might be as in Figure 1.

|

| Figure 1: Likely torque/speed curves of engine |

In two-stroke mode the admission of the new charge and exhaust of the old one have to take place simultaneously in a rather short time around bottom dead centre. To that end, the exhaust valves have been made larger than the inlet valves, and the engine is supercharged. This requires a shaft-driven compressor rather than a turbocharger, since although the latter does indeed raise the inlet manifold pressure, the pressure drop across the turbine also raises the exhaust pressure. A shaft-driven compressor gives a positive pressure-drop across the whole engine, and thus speeds up both inflow and outflow. A radial compressor, more efficient than the traditional Roots blower, has been used, and indeed turbochargers have been used in addition, presumably to increase the mass flows. The fuel is injected directly into the cylinders, primarily to avoid loss of charge in the two-stroke mode.

The valves are top-entry poppet valves, (side-entry ones would short-circuit the charge), and in the experimental prototype are operated electro-hydraulically rather than by a camshaft, so that the timing can be easily varied.

The engine runs successfully, with performance much as expected, though it takes two seconds to change from four-stroke to two-stroke. On a simulated driving cycle for a 1815 kg vehicle in which a 2.1 litre two/four-stroke engine replaced a 3.5 litre conventional four-stroke, the fuel consumption and CO2 emission were reduced by 19% or 27% (depending on the cycle being simulated).

There is still a lot to do, including the development of a mechanical valve drive system. The intention is to demonstrate the use of a V6 engine in a Jaguar.

The work is being supported by the Department of Trade and Industry, with various collaborators.

Reference

Osborne RJ et al, Development of a multi-cylinder two-stroke/four-stroke switching gasoline engine, 2009 IMechE Conference on Low Carbon Vehicles

| << Previous article | Contents | Next article >> |

| SOUE News Home |

Copyright © 2009 Society of Oxford University Engineers |

SOUE Home |