| Issue 6 |

In recent months there has been significant discussion about the possibility of constructing new Nuclear Power plants in the UK. This article discusses some of the issues which are likely to influence the debate, and reviews some of the available technologies.

There are currently ten operational Nuclear Power Stations in the UK, two "Magnox" stations, seven "AGR" stations and one "PWR" station which equates to 19 power reactors in total. There are also 24 power reactors in various stages of decommissioning.

The nuclear power programme grew out of the nuclear weapons programme post World War II. At the end of the war the Government made the decision that, like the USA, Britain was to develop nuclear weapons. In 1946 the US government decided it would not share weapons technology with its WW2 allies and so Britain was forced to develop its weapons in isolation. At the time nuclear explosive devices could be "fuelled" by highly enriched uranium (the Hiroshima bomb) or by plutonium (the Nagasaki bomb). A plutonium bomb is safer to construct and handle, and does not require any enrichment facilities, although a nuclear fission reactor is required to generate plutonium from natural uranium. The UK government decided to pursue development of a plutonium device based on economics and safety. Thus the UK required a fission reactor to generate plutonium. To build a nuclear fission reactor requires a moderator to slow down the fast-moving neutrons released in the fission process, to increase the probability of these neutrons creating further fissions and sustaining the chain reaction. In the late 1940s there were only three credible moderators available - light water, heavy water (i.e. water molecules with a deuterium atom in place of hydrogen) and graphite. Light water reactors require enriched uranium which was not available in the UK at the time, heavy water reactors require a source of heavy water (again not easily available), thus a graphite moderated design was selected for the UK. The US had been working on a graphite moderated, light water cooled reactor but because of interaction between the water and graphite, the moderation was unpredictable with consequent safety concerns. For this reason the UK decided to build a graphite moderated, air cooled reactor (non power generating) to produce plutonium and these were constructed at Windscale in Cumbria and became known as 'the Windscale Piles'.

As the 'Cold War' began the government took the decision to ramp up plutonium production. Further plutonium producing reactors were required, but it was recognised that the 'waste' energy from the reactor could be harnessed to generate electricity. The moderator of these proposed reactors was to be graphite (for the same reasons as outlined above) and thus a gaseous coolant was considered to be the most obvious choice. Hydrogen, helium, carbon dioxide and nitrogen were considered. CO2 was selected as the best available compromise (hydrogen is flammable, helium was too expensive to produce and nitrogen is a neutron absorber) and thus the so-called Magnox programme began (named for the MAGnesium Non-OXidising fuel cladding).

Calder Hall (commissioned in 1956) and its sister plant at Chapelcross (1959) were the first nuclear power stations in the UK; however these reactors were optimised for military purposes (plutonium production). Thus Berkeley Power Station in Gloucestershire, a "Magnox" plant commissioned in 1962 is considered the first civil nuclear power station in the UK. The Magnox programme consisted of a further eight stations in the UK (and two overseas).

The Magnox programme was followed by construction of seven Advanced Gas Cooled Reactor (AGR) stations commissioned between 1977 and 1988. The AGR programme began because the Magnox programme was thought to have reached the end of its useful life and there were perceived to be economies of scale (and improved reliability) in building a nuclear reactor to generate steam for the standard design of 660 MWe turbine-generator used at conventional fossil fired plants. The AGR design was based on the experience of the Magnox design, but included several significant improvements. High temperature gas cooled reactors offer a number of advantages over light water cooled reactors, for instance low operator radiation dose, on-load refuelling capability and long operator response times to faults. However the gas cooled reactor is undeniably more complex, more expensive and requires unusual materials for construction.

During the early 1980s there was significant pressure on the Central Electricity Generating Board (CEGB) from government and industry to consider the construction of a pressurised water reactor (PWR). This was felt to be the technology of choice around the world; the PWR was judged to be cheaper to construct, to be more reliable than gas cooled equivalents, to be constructed of more factory built components (for example there was no need for a complex concrete pressure vessel); and successful construction of a PWR from components manufactured in the UK was predicted to provide UK manufacturing industry with export opportunities. The South of Scotland Electricity Board (SSEB) advocated further AGR construction based on the success of Heysham 2 and Torness, but the CEGB settled on construction of a fleet of PWRs, the first of which, Sizewell B began construction in 1986 and was commissioned in 1995. In 1989, with electricity privatisation looming the plans for the second PWR, Hinkley Point C were put on the back burner, and eventually abandoned.

Table 1 (below) presents a list of UK nuclear power reactors. The current lifetime of the gas cooled reactors is such that by 2023 all existing plants will have closed with the exception of Sizewell B. Sizewell B was designed for a 40 year life, but extension to 60 years is widely considered to be practical.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Notes:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 1: List of UK nuclear power reactors in order of construction |

In the 2006 UK Energy Review the government announced that: "Government considers that nuclear has a role to play in the future UK generating mix alongside other low carbon generating options". The subsequent Energy White Paper in May 2007 stated "it is the government's preliminary view that it is in the public interest to give the private sector the option of investing in new nuclear power stations".

The reasons for this policy statement can be summarised as follows:

Note that the energy review and subsequent white paper have not recommended construction of new nuclear stations, and indeed, any new nuclear build would have to be entirely financed from the private sector. The white paper describes the government's views on nuclear as 'preliminary' and a consultation document accompanied the white paper. The public consultation process is due to be completed in October 2007.

Obviously there are significant issues surrounding siting, financing, regulating and planning approval that need to be overcome before any new project will begin. To secure financing of such a large-scale project it is likely that the operator will attempt to secure fixed price sales contracts for a significant proportion of the station lifetime.

Within the EU there are currently two nuclear power stations under construction - Olkiluoto 3, Finland, where construction began in 2005 and Flamanville, France, where construction is due to start in late 2007. Both of these projects involve construction of the AREVA designed European Pressurised Water Reactor (EPR). The French remain committed to a nuclear power programme, as are Japan, South Korea, China and India. On the other hand, Germany and Sweden have existing nuclear power stations which their national governments have committed to phasing out. In the USA three consortia are pursuing an "early site permit" to evaluate specific sites for construction of new nuclear units.

Across the globe there is a trend to pursue life extension of existing nuclear facilities. The large initial cost of a nuclear plant means that if replacement of the components is technically feasible, it is probably cost-effective to extend the life of the plant, even if a long shutdown is required. Several nuclear plants around the world are pursuing agreement in principle to a 60 year operational lifetime (compared to original design lives of 30-40 years).

It should be noted that whilst life extensions are being investigated, it is unlikely that any operating UK gas reactors will achieve more than a 40 year life.

The process for determining the site of a new nuclear reactor will be extremely controversial. It is probable that new build in the UK will be on sites adjacent to existing nuclear facilities (operating and decommissioned power stations or experimental facilities). Most of these sites have connections to the supergrid, and all have local skilled labour, for employment on site and in supporting infrastructure. The sites are all suitable from a geological point of view and there are supplies of cooling water available (most sites are coastal). In general the local population is supportive of nuclear stations and the benefits they bring to the economy. In addition, with existing facilities approaching the end of their lifetime, new build could offer the workforce a transition into a new facility.

Other sites have been considered in the past, and sites close to existing conventional power stations have many of the required characteristics, but it is most likely that the first sites to be considered for a new "fleet" would be where there are existing nuclear facilities.

The process for deciding on a suitable site is most likely to involve consultation at a national level, once candidate sites have been chosen. The ongoing public consultation into whether to construct new nuclear power plants is accompanied by a separate consultation document on 'Strategic Siting Assessment Processes for New Nuclear Power Stations'. The outcome of this consultation is likely to be a new siting assessment process.

It is considered likely that the UK would return to the practice of building twin reactor stations at each site, to provide economies of scale at each location and to minimise the number of nuclear reactor locations.

Construction of a new nuclear station in this country will raise some unique issues which have not yet been faced in the UK. In the past the Central Electricity Generating Board was responsible for determining nuclear power strategy. In future there may be competing organisations proposing to build on different sites, using different reactor designs, with different safety and operational philosophies.

The UK regulator, the Nuclear Installations Inspectorate (NII), does not have the resources to assess all technologies and determine which of these is acceptable for the UK. Thus there is a risk that following detailed engineering assessment the NII may require redesign work or insist on the addition of engineered safety features. It is obvious that this will increase the cost, may lead to delays in construction, and may even adversely affect plant reliability. Such design changes could make UK reactors unique in comparison with nominally identical reactor types elsewhere in the world.

As a result the government have announced their intention to utilise a Generic Design Assessment (GDA) process whereby NII will undertake an up-front assessment of designs submitted by vendors. This assessment process is expected to take three to four years. It is anticipated that after GDA is complete, the design will be frozen and can then be assessed for its suitability at a particular site, which is expected to be relatively straightforward. Planning approval must then be sought for construction.

It is widely accepted that a repeat of the more than two years of public inquiry into the construction of Sizewell B would prevent private investors from considering nuclear power. In May 2007 a government White Paper on Planning Policy made provision for a National Planning policy and a new central planning body to make decisions regarding major strategic infrastructure developments (particularly power generation) such as nuclear stations. This white paper is in the consultation phase at the time of writing and therefore the final outcome is not yet clear.

There is a wide range of Nuclear generation technologies available but I have chosen to discuss four: the AREVA EPR, the Westinghouse AP1000, the AECL CANDU and the GE ESBWR. All four of these designs have been submitted to NII for Generic Design Assessment.

It should be noted that the construction of a new generation of nuclear power plants in the UK offers an opportunity. Because of the existing fleet of gas-cooled reactors, and the "one-off" at Sizewell B, the UK is not "bought in" to any currently available technology. Unlike many other nations, the UK has an opportunity to forge a path in a new direction if we choose to do so. This strategy is not without risks; however the pre-eminence of light water technology reactors in the world does not mean that these are the "best" designs, just that these have been more successfully marketed.

Note that no 'fast' breeder type reactor is available commercially - all of the technologies being considered for power generation at this stage are thermal nuclear fission reactors.

The EPR is a pressurised light water reactor based on the successful French N4 and German KONVOI PWR designs. AREVA (a consortium of Framatome and Siemens) has orders for two EPRs in Europe (in Finland and in France).

The basic EPR design is a 1600 MWe 4-loop (i.e. four steam generators) PWR, with a thermal efficiency of 36% and a design life of 60 years. By redesign of the fuel cycle and refuelling interval, the EPR is a more efficient unit than previous PWR designs.

The EPR adds additional safety features, including four independent 'trains' of automatic safety systems to improve tolerance to fault situations, a containment structure designed to withstand aircraft impact, and severe accident mitigation against the possibility of core melt.

Because the EPR is a conventional PWR, with engineered safety features, building on existing reactor technology, it is the design most like Sizewell B and as such would probably be the most straightforward to license in the UK. However, some commentators consider that the size of the EPR makes it unwieldy for a relatively small national grid, since in the event of a random reactor shutdown, the loss of 1600 MWe may cause significant grid instability. Like all existing UK nuclear stations the EPR makes use of diverse and redundant automatic protection systems designed to operate to protect the reactor in the event of a fault. However, other reactor designs make use of passive safety features, without the need for systems to operate to maintain safety. There is a clash between these two design philosophies but it may be that the EPR is considered to be the last design of a previous generation.

In 2006 the government announced a strategic nuclear technology alliance with the French. Because of this alliance, and the similarity to Sizewell B many experts consider that the next UK nuclear reactor is most likely to be an EPR.

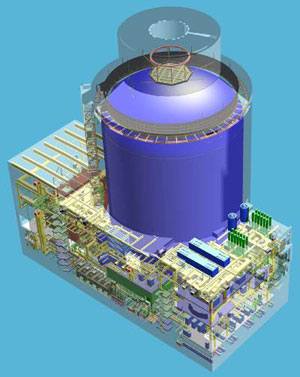

| |

| Layout of AREVA EPR reactor | |

|

The Westinghouse AP1000 is a ~1150 MWe pressurised light water reactor.

The basic electricity generating unit is very similar to the EPR design, although it is based on only two loops rather than four, and achieves a thermal efficiency closer to 33%. The size of the generating unit is similar to previous generations of PWR (and very similar to Sizewell B), therefore it does not have the same concerns regarding grid stability.

It is in the design of the safety features that the AP1000 differs from existing PWRs. The principle of the AP1000 is to simplify the design of the reactor by providing passive protection from faults and hazards and thus avoid the need for complex control schemes, and reduce the burden on operators during faults. The idea is to achieve safety by design, rather than the established 'defence in depth' (multiple diverse and redundant safety systems) approach. A good example is the provision of reactor cooling in a loss of electrical grid connection fault. The AP1000 is able to maintain core cooling via natural circulation of cooling water, and provision of an induced-draught cooling tower as part of the containment structure, thus avoiding the need for standby emergency generators.

|

| Diagram of AP1000 reactor |

The intent is that by simplifying the plant, the initial cost of the reactor is reduced, and the potential for accidents is reduced because there is less plant to maintain, or malfunction. Westinghouse claim that the AP1000 requires 50% fewer valves, 83% less pipework, 87% less control cabling and 35% fewer pumps than existing PWR designs of a similar capacity. In developing the AP1000 Westinghouse have challenged the accepted wisdom that employing diverse and redundant automatic protection systems is the "best way" to safeguard a nuclear reactor. It is not yet clear whether the passive safety systems will prove popular with operators and regulators.

The challenge for Westinghouse is to convince the UK regulators that the passive design features can achieve the required performance - it is a radical departure from any reactor constructed in Britain. In addition, no AP1000 has yet been constructed and there is a significant risk that the construction costs will rise.

However, the claimed low construction and operating costs, and the passive safety features must make the AP1000 a strong contender.

The CANDU 6 (CANadian Deuterium Uranium) reactor design has become a popular alternative to the more common light water reactor technologies. The CANDU reactor is a heavy water moderated, light water cooled reactor. There are 32 CANDU reactors across the world and AECL offer a CANDU 6 design of 750 MWe capacity and are developing the ~1000 MWe ACR (Advanced CANDU Reactor)

The CANDU reactor is extremely flexible in terms of the fuels it can use, for instance it can be fuelled with natural uranium and in this case there would be no need for complex, energy intensive and costly uranium enrichment facilities required for conventional light water technologies which may be an attractive feature. When using natural uranium as a fuel the fuel dwell within the reactor ('burn up') is low in comparison with using enriched fuel (approximately ¼ of the burn up of a light water reactor). Thus the cost avoided in enrichment may be spent on extra fuel or reprocessing. The CANDU reactor can be refuelled on load (a feature it shares with gas cooled reactors), which is attractive from a commercial viewpoint and important given the short fuel dwell if natural uranium fuel is used. The flexibility of fuelling of the CANDU design is one of the key attractions, for example within certain constraints it is possible to remove a 'used' fuel assembly from a PWR and install it into a CANDU reactor and continue to generate power.

The fact that the reactor can be refuelled on load means that the containment building is designed for access at power (not the case for most light water cooled reactors) and therefore there is better access for maintenance and fault diagnosis.

In addition, AECL license the rights to build CANDU reactors, thus it is possible that UK manufacturing industry could benefit from construction of a CANDU reactor.

A heavy water moderated, light water cooled reactor has operated in the UK already (SGHWR at Winfrith) and there is also some experience within the UK of this technology since prior to financial collapse in 2004, British Energy owned and operated the Bruce Nuclear Plant in Ontario (which consists of eight CANDU reactors). As with the AP1000 the smaller size of the CANDU generating units gives little cause for concern with regard to grid stability.

The downside of the CANDU design is that the technology is relatively unusual, it requires a heavy water moderator, and the CANDU 6 units are small in size, but as discussed there are many advantages that make the CANDU a popular alternative choice.

The ESBWR is an evolution of previous General Electric Boiling Water Reactor designs, being a 1560 MWe, light water cooled reactor. In a boiling water reactor there is no secondary heat removal circuit. Light water is passed over the fuel and boils to form steam within the reactor - the steam generated is then passed direct to the turbine set thus increasing the cycle efficiency (the ESBWR cycle efficiency is predicted to be ~35%). Although this delivers improved efficiency it complicates turbine maintenance because of radiological considerations (the turbine is in direct contact with the nuclear fuel coolant), but the SGHWR at Winfrith utilised this type of turbine cycle and thus it is not without precedent in the UK.

Like the EPR the design builds on previous reactor technology using some identical components but like the AP1000 it makes use of passive operating and safety features. Thus the ESBWR may be seen as a compromise between the competing designs.

One key feature is the elimination of circulation pumps to drive water around the pressure vessel, with the ESBWR relying on natural circulation instead. This concept is extended to the safety systems, which also rely on passive features, for instance avoiding the need for emergency power on site.

Also, like the EPR, the basic generating unit of an ESBWR is very large at ~1600 MWe, and therefore there are the same concerns with regard to electrical grid stability in the event of an unplanned shutdown.

A Boiling Water Reactor has never been built on a commercial scale in the UK, but BWR technology is popular throughout the world (especially in the USA and Japan). The ESBWR offers a compromise between the EPR and AP1000, builds on existing successful designs and BWR technology is in wide use, therefore it is a strong contender.

Conventional reactor technologies "burn" only approximately 3% of the fissile material in the fuel before it becomes uneconomic. Reprocessing technology is designed to extract the spent fuel to enable the remaining 97% to be re-used. Reprocessing is controversial owing to the generation of concentrated waste, the separation of weapons grade isotopes and the uncertain economics. Currently only four countries in the world undertake reprocessing on a commercial scale (UK, France, Russia and Japan).

Because of reprocessing, spent nuclear fuel may be considered a resource (because new fuel can be made from old) or alternatively it may be considered as waste.

Currently the UK has a "stockpile" of ~1500 m3 of high-level radioactive waste and, in addition, significant volumes of spent fuel considered 'resource' and therefore not classified as waste. The high-level waste consists of a mixture of different radio-isotopes, some of which will take 'only' a few hundred years to become safe, but others will take many hundreds of thousands of years to decay such that they are safe.

In addition to the high-level waste, nuclear power reactors generate significant quantities of intermediate-level waste (mostly components irradiated within the reactor pressure vessel). To date there is no agreed means to dispose of either high-level or intermediate-level wastes in the UK. Other countries are significantly further on in the process of engineering a safe waste disposal route.

In 2006 the Commission for Radioactive Waste Management (CoRWM) concluded that the best option for "final disposal" was to build a sub-surface geological repository. The key advantage offered by geological disposal is that timescales of hundreds of thousands of years are short in geological terms. By choosing a site carefully, geologists can have a high degree of confidence of how the rock formations will behave. The deep geological repository is the technology of choice for many nations, and several have progressed to very advanced feasibility studies and experimental geological facilities (for example the Yucca Mountain facility in the Nevada desert, USA).

The lack of a disposal site and agreed technology creates significant problems for those sites currently being decommissioned since the detail of the packaging for the waste cannot be finalised until the design of the disposal facility is agreed. Therefore interim solutions must be sought for all the decommissioned power plants, and this may lead to waste being re-packaged in future. Clearly this in uneconomic, but it is also bad radiological practice since operators will have to be exposed to the waste more than once. Thus solving the issue of the waste disposal is considered critical to progressing decommissioning effectively and therefore completing the final economic assessment of nuclear power.

Progress in the disposal of nuclear waste in the UK requires detailed assessment of suitable geological formations and the commitment to research suitable medium term storage options whilst the final disposal site is determined, designed and constructed.

Andy Pyle read Engineering Science at Balliol, 1995-9, and is now Group Head, Programmes and Design Engineering, at Heysham 2 Nuclear Power Station, an AGR plant in Lancashire, owned by British Energy. He has worked for British Energy for eight years, in a variety of roles within Central Engineering Support, and at Heysham 2. He is a Chartered Mechanical Engineer, sitting on the Nuclear Power Committee of the IMechE, and is also a member of the Institution of Engineering and Technology. In 2005 Andy attended the inaugural World Nuclear University Summer Institute, held at the Idaho National Engineering Laboratory, USA. Before joining British Energy Andy was sponsored through his Oxford degree by Siemens Power Generation Ltd (formerly CA Parsons of Newcastle).

| << Previous article | Contents | Next article >> |

| SOUE News Home |

Copyright © 2007 Society of Oxford University Engineers |

SOUE Home |