| Issue 2 |

Turbine heat transfer and aerodynamics research was initiated in the Department by Professors Donald Schultz and Terry Jones with their work on shock tube tests. The research is now closely associated with aero-engines and much of the work is carried out within the Rolls-Royce University Technology Centre. Engine manufacturers, such as Rolls-Royce, strive to produce better efficiencies and reduced fuel consumption, for both economic and environmental reasons. This can be achieved by increasing the temperature at which the engine operates. Currently, the hot gas and combustion products forming the gas stream in a gas turbine engine can reach temperatures of 2375K, with some component temperatures at about 950°C. The lower component temperatures are achieved through careful design and control of both internal blade air cooling and external film cooling using cooler compressor air. Much of the work carried out by Dr Ireland and his colleagues is aimed at the determination of temperature distributions using both sophisticated experimental techniques and the development of accurate mathematical models for boundary layers. An important and difficult problem that arises in the development of the theoretical models is that of turbulence.

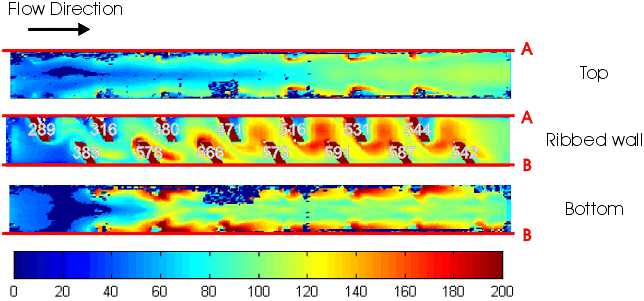

Dimensional analysis is often used by the researchers in order to design tests that provide 'similarity' with aero-engine component conditions; that is, using dimensional analysis, laboratory tests can be designed which simulate the conditions to which engine components are subjected, but which are considerably easier to achieve than the actual engine conditions. In such experiments, a number of novel techniques are used to measure accurately the temperatures of model engine components. These include the use of 'chips' in the Rotor facility run by Professor Ainsworth and his team. The chips are implanted into the blades and this enables high frequency heat flux and pressure information to be obtained over just one twelfth of a second. Liquid crystal techniques are also used to measure temperatures in low speed models. Here, components are coated with liquid crystals which change colour according to the temperature. This technique is used in particular for determination of internal cooling duct heat transfer coefficients. The technique allows resolution equivalent to six microns in the actual film cooling holes, which have a diameter of about 0.3mm. This work has enabled the investigation of the use of turbulators within the cooling ducts to improve heat transfer. The function of the turbulator is to destroy the boundary layer and hence increase the heat transfer coefficient. Some results are shown in the figure below in which the ribs, or turbulators, can be seen.

The experimental techniques developed are essential since unfortunately, computational fluid dynamics simulations are currently unable to predict correctly the gas velocities in the cooling ducts.

Dr Ireland completed his fascinating presentation by giving other examples in which his research finds application. These include marine engines and fire event modelling. Turbomachinery research is clearly still thriving in Oxford, with many challenges ahead; circumstances with which Donald Schultz would no doubt be well pleased.

|

| Turbulators destroying the boundary layer and increasing heat transfer |

| << Previous article | Contents | Next article >> |

| SOUE News Home |

Copyright © 2003 Society of Oxford University Engineers |

SOUE Home |