| Issue 5 |

Lectures before engineering societies are more usually about new developments. This one is decidedly retrospective, back to Classical Greece and its warships.

On structures of the Classical period, Vitruvius, a Roman, wrote ten books on architecture, building and military engineering between 30 and 20 BC. He mentions ships but unfortunately in little detail. What we would now regard as useful written information about ships in the past, as about other structures, is indeed rare. Representations are decidedly unreliable as regards essential proportions. The art, concepts and mental stock-in-trade of constructors of all kinds in most of the past seem not to have been valued or considered of much intellectual interest by the writers and elites of their societies, in spite of the scientific and technical achievements of the Greeks, Romans, and Arabs, not to mention the Chinese.

It is therefore not so surprising that 'rude mechanics' tended to keep their knowledge to themselves. Lack of theoretical models of their artefacts, added no doubt to personal penalties if they caused disasters, very sensibly made them to stick to rules based on experience of what worked, no matter why. All this makes reliable replication of ancient artefacts, particularly if they are mechanisms and actually have to operate, a tricky business.

|

Having, as it were, very briefly commented upon the past technical scene, it is time to introduce my subject, the ancient Greek trireme warship of the fourth century BC (see picture of reconstruction, above). It is a rare and interesting exception technically in that there is a useful amount of evidence about it. Surviving Athenian records and literature provide enough clues to show that it was a finely made and extreme design of ship.

Triremes had nevertheless been a puzzle since the Renaissance when classical texts began to be studied again by scholars. It was clear from that surviving literature that the trireme was the main instrument of naval power in the Mediterranean during the fifth and fourth centuries BC, an important period historically. The crucial naval battle of Salamis between the Greeks and the Persian Empire was fought with well over a thousand triremes. Athenian supremacy at sea afterwards enabled that city state to flower culturally and leave a legacy that still influences the Western world today. Though later superseded in the battle line by much heavier ships armed with troops and missiles, triremes, very possibly of designs varying as time went on, served in the Roman navy and they are mentioned by Tacitus operating in the Netherlands in the first century AD. From the first mention of it in the seventh century BC, that gives the trireme as a type of warship an operational life as long as eight centuries - a period equal to that from Magna Carta to the present day!

The trireme may have been important historically, but it itself remained a mystery. What exactly was it? Why was it developed? How was it built? How did it work? What could it do? A reconstruction of an Athenian trireme has now been built and operated to find out, and a very instructive project it has proved to be. The ship was built in Greece under contract from the Hellenic Navy and it belongs to that navy. The project itself has been reported and published in this country.

|

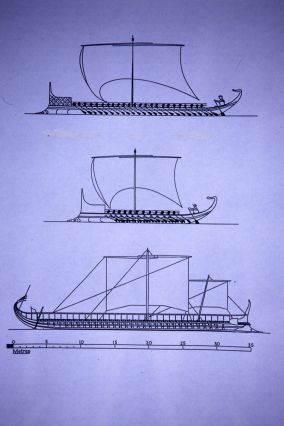

It was clear from the literature that triremes were evolved from earlier warships (above), the top two shown here, at the top the 50-oared single-level ship and in the middle the later two-level 50-oared ship. The trireme represented an astonishingly large step from the middle ship. Its cost to build and maintain would have been four or five times as great and, more importantly, crewing costs would have been four times as great. Remember these crews were paid, not slaves. Why make such a big step? What was the naval advantage? There must have been one, but surviving literature is silent. However, as a naval architect one can surmise that it lay in greater sustainable speed, suggesting the need to project naval power and to be able to deal with pirates which were endemic in the Mediterranean. What remains surprising is that such an advantage was enough to make the much greater cost worthwhile, but obviously this advantage, and possibly others not yet identified, were sufficient for the trireme to have been the standard ship of the line in the Mediterranean for about three centuries.

One has to bear in mind that warships had grown from small 20- and 30-oared ships built mainly to carry troops for fighting ashore. Conflicts between warships led to the use of rams to put enemies out of action, and the better manoeuvrability of shorter ships in battle could well have been behind the idea of putting the same number of oarcrew on two levels. In rate of turning and acceleration, both valuable in a ramming battle, the trireme was no better than the two-level 50-oared ship, which actually continued in service alongside triremes for some time.

Scholars had been arguing about the trireme for nigh on five centuries, but it needed the discovery of two sunken wrecks of oared ships with long hulls, and the application of our present knowledge of physics and materials, in short engineering or naval architecture, to the ancient evidence to arrive at a usefully close solution to the puzzle. It happens that surviving evidence about the Athenian version of the trireme, at least, includes sufficient numbers and measurements to lead to the possibility of a reconstruction which would be worthwhile without necessarily accurately replicating every detail. For organising that evidence into a useful form we have to be grateful mainly to the late John Morrison, a Cambridge classicist who published his book, Greek Oared Ships, in 1968. I shall not however go into the details of that evidence here because that would need a lecture to itself.

If the design of the trireme had been a fairly relaxed affair, comfortably within physical limits, no one particular reconstruction might have been worthwhile because there would have been room for too much choice among several possible designs. But, like so many weapons in all ages, the trireme turned out to be a design at the limits of practical possibility. Keeping to the numerical evidence while designing a ship, which would be satisfactorily stable, strong enough and likely to perform well enough under oar or sail, hemmed in the main dimensions and arrangement of parts within close limits. The ship had to be of the authentic build and shape demonstrated by the very few other remains of long, oared Mediterranean ships to have been excavated. No wrecks of actual warships have so far been found because warships would not have sunk, being unballasted and made of timber. The one found in the 1970s near Marsala, Sicily, was probably a fleet supply ship and it had been carrying ballast. To sink, a wooden ship has to be carrying enough cargo or ballast to raise its mean density above that of seawater.

|

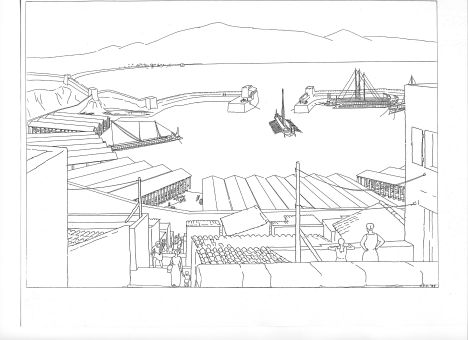

The hull of the reconstruction had be narrow enough to fit inside ship sheds in Piraeus where Athenian triremes were kept (above). Their foundations have been excavated and measured. The hull had to house an oarcrew of 170 men, each able to work one oar effectively while sitting at each of three levels in the ship, one level above the other. That imposed limits of waterline breadth, displacement and height of centre of gravity to obtain sufficient stability for oarsmen to work properly. Oarsmen do not take kindly to rowing in rocking boats.

The recorded length of the oars, the likely speeds of triremes, consequent oar gearing and the maximum practicable slope when blades were immersed, as well as stability, limited the height of the top of the hull above water. The hull was therefore very shallow for the length necessary to house the oarcrew. The waterline length was more than 13 times the depth of the hull. That ratio is about twice that allowed by Lloyd's Rules for wooden ships in the 19th century unless they were strapped with iron to cope with hull stresses at sea. The hull strength of the trireme seemed therefore problematic and on the limit for a wooden hull. I should mention that its underwater form is as slender as that of a modern steel frigate.

|

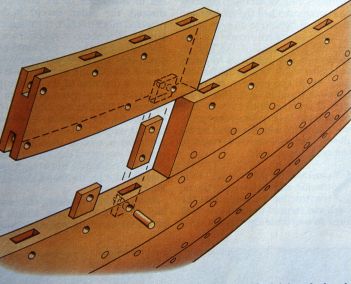

Here, three more pieces of evidence came into play to enable the hull to be both strong enough and authentic. First, the planking of all ships in the Mediterranean up to about the fifth century AD was fastened, one plank to the next, by pegged tenons set into their edges (above). This was then the usual way carpenters joined planks side-by-side. But by resisting any shear stresses causing planks to slide upon each other, plank tenons, if tightly fitted, could make the planking into a shear carrying shell in the modern sense, besides holding the plank seams together tightly to be watertight. In ordinary latter-day wooden ships, shear between planks is transmitted only by the friction of caulking rammed tightly into the seams. In the wrecks of the ancient long ships which I have already mentioned, the tenons are thicker and more closely spaced than in the shorter and generally smaller merchant ship hulls, wrecks of which have been excavated in large numbers in the Mediterranean. As fitting these tenons, if they are to resist shear in the shell stiffly, has to be exact (probably by a simultaneous crush-fit) they must have involved a lot of careful fitting work, so it is most unlikely that tenons in long ships were closely spaced for no good reason. Indeed, calculations bear this out, though they are necessarily rather simplified in being applied to wood. The maximum likely shear stress in the shell of the trireme hull indicates that tenons had to be closely spaced to prevent crushing when the ship was on the crest of the worst wave she was likely, by intention at least, to encounter.

To design the reconstruction the height, from trough to crest, of this wave had to be judged. I decided upon a wave of length equal to the waterline length and 1/40th as high which I thought would be about the maximum in which the upper two levels of oars could be rowed, and so about the worst to which a commander would expose the ship to before running for shelter. That height relative to length is only about half what is normally taken in designing ships today. Nevertheless a total of not far short of 20,000 tenons were needed in the hull to be likely to withstand that reduced wave.

A wooden shell of planks tightly fastened together with tight seams would expand across the breadths of the planks when wet and so stretch the transverse frames crossing them. That action has been known to break frames. In ancient Mediterranean ships, however, transverse frames were fitted in three tiers overlapping each other, but not connected to form continuous frames. Frames were also bolted to the shell by copper bolts driven up pine dowels whose relatively soft timber would crush fairly easily to allow the shell to slide a little on each relatively short piece of framing.

The second piece of evidence concerning strength was about great ropes, 47 mm or so in diameter, and nearly twice the ship's length. Two were rigged in each ship when on active service, and two more were carried aboard as spares. A decree laid down the number of men required to rig them in a trireme. The inscription about them is unfortunately damaged, but the space occupied by the missing number indicates that it was probably 50. They were important pieces of kit because their export from Athens was a capital offence.

It seems most likely that these ropes, hypozomata in Greek, that is undergirding, acted as tensioned tendons in the hull girder. On the wave being considered, the maximum bending stresses in the hull, amidships, would be, in newtons/mm2, about -6.7 in the keel and +5.7 at the top of the hull. These would be generated when the ship was on the crest of a wave when the loading on the hull would cause the ends to deflect downwards, known as hogging. Now, Sir William White, an eminent naval architect of the 19th century (a time when both bending and shear in ships had been understood and when wooden ships were still in common use), stated that a tensile stress of only +2.9 was allowable in wooden ships' structure containing scarfed joints, while if there were no scarfs where the structure was heavily stressed, +4.6 would be allowable. Plainly the trireme was heavily stressed in bending as well as in shear. If the hypozomata were rigged fore and aft from end to end along the middle line of the hull just under the main beams (after all, they had to be under something!), and tensioned to 13.5 tonnes force, that maximum stress would be reduced to White's allowable level for structure without scarfs. On this point, there is a third piece of evidence, a helpful reference in the literature to the need for long timbers in building warships. One may surmise that such timbers would have been used to form the upper edges of the hull to avoid scarfs where bending stresses were greatest.

Rope tendons had been used in ships before, for instance in ancient Egyptian cargo ships where they are shown in bas reliefs looped under each rising end of the hull and then arching up over struts to form a hogging truss to prevent the ends of the hull from dropping. Hogging trusses have more recently been parts of the design of several types of shallow hulls, for instance Mississippi steamboats and ferries more generally. The trireme's hypozomata was more probably a straight tendon. Plainly that could only impose a horizontal thrust on the ends of hull and affect longitudinal horizontal, that is bending, stresses. It could reduce bending stresses in hogging but do nothing to reduce the shearing component of stresses generated by that loading. As is usually the case in ships, hogging is more severe than its opposite, sagging, when in the trough of a wave.

How the hypozomata were tensioned remains a mystery. In the Egyptian ships the hogging trusses were plainly tensioned by twisting them together, making what is often called a Spanish Windlass. That is not a very efficient mechanism because in twisting the ropes they are bent into helices, so that bending stresses are generated which are about as great as the direct tension which is desired. However, it is clear enough that that was what the Egyptians did. In latter day sailing ships standing rigging was invariably set up by three-fold purchases in which the blocks were without sheaves but greased. They are called deadeyes. I think that method is more likely to have been used in triremes also. Natural fibres relax under sustained tension, so they would have had to be tightened repeatedly, just like sailing ships' hemp standing rigging. That would explain why a spare pair of ropes were carried in triremes, presumably to replace the ropes when they had stretched so much that they could be tightened no more. They might then have recovered somewhat but they would probably have been shortened for further use by refitting the deadeyes. That also was done in latter-day sailing ships when mast shrouds had stretched so that the deadeyes were in contact, 'two-blocks' as it was said.

In the reconstruction, natural fibre ropes could not be obtained in Greece, certainly not in the required size, nor could synthetic fibre ropes with about the same elastic modulus as hemp, so we had to make do with a steel rope. Being much stiffer, and being above the flexural neutral axis of the hull, its tension varied as the hull bent on waves, whereas a natural fibre rope would have exerted a substantially constant tension. That variation in the reconstruction was rather alarming because one could not be sure how big the tension would become on an exceptional wave. On that account I settled for a tension in still water of 9 tonnes force. If one of the timber anchorages were to fail, the steel rope would have snaked down the hull. The photo below is of a view down the hull where there were 54 rowers sitting on either side outside the pillars. The rope ran down the middle just under the gangway overhead. The pairs of pillars would have protected rowers but the rope was also securely triced up to the beams at a number of points as a further precaution.

This slide also shows the hull beams and that the hull was structurally speaking an open trough. Open hulls tend to have low frequencies of torsional vibration in the fundamental mode and it seemed to me that it would be most undesirable for that frequency to be within the range of the striking rates of the oars. Without any evidence to support it, I therefore arranged stiff horizontal knees at the ends of the beams near the middle line of the ship, crossbracing between the beams in an effort structurally to close the open trough to make the hull behave more like a tube or decked hull. The idea was to force the beams, when the hull was twisting, to be bent into three-noded curves and hence be much stiffer. The torsional frequency of vibration of the loaded hull is probably about 70 cycles a minute, well above the maximum practicable rate of striking with the oars. In any case, no torsional oscillations were noticeable during rowing trials. Here, it may interesting to note that the 1829 Oxford Boat Race boat, now in the Henley Museum, proved to have become alarmingly floppy in torsion when rowed by its second owners in Scotland, and photographs of the replicas built and raced recently show additional internal longitudinal aluminium sheet triangular spines set between keel and thwarts, presumably to stiffen the hulls torsionally!

I have thus far spoken briefly about what the trireme was, probably why it was developed and more fully about how it was built and some of the structural engineering concepts involved.

Now, how did it work and what could it do? These questions called for some experimental archaeology on quite a large scale, maybe the largest archaeological experiments yet carried out. A trireme needed 200 men besides a captain to man it - 170 oarcrew in three classes, ten soldiers, four archers, three officers, a helmsman, a shipwright, a piper and ten seamen. Nowadays that would be enough to man a frigate! And Athens at one time had about two or three hundred triremes, so at least about 40,000 men were trained and available at need to man them. The sea trials of the reconstruction, Olympias, were quite a large operation, the cost of which would have been prohibitive unless the Hellenic Navy had generously provided accommodation in some barracks at Poros, 40 miles south of Athens, and unless sufficient oarsmen and women were willing at their own expense to come to Greece and feed themselves for the trials periods of two weeks in August.

Making Olympias work under oar or under sail was quite an experience. No one in our crews had rowed in anything larger than an eight, nor, I guess, had any of them taken part as a team in a large scale co-ordinated manual job such as navvying on a railway cutting or embankment. But here (below) they are in their places on board. Oar blades were only a foot apart in the water, so synchronism in rowing was essential. Timing and clashing of oars were pretty terrible to begin with, and in motion the ship was likened by one rowing master to a spastic centipede. However, after about two days things improved quickly and so did morale. The crew could speak of nothing else in the local tavernas but this extraordinary experience, they said of a lifetime, and their own achievements.

|

We were particularly keen to explore the performance of the reconstruction under oar in view of the trireme's reputation for speed and manoeuvrability. We also tested her under sail and having found that she handled well under sail, a most important aspect of operating the ship, we concentrated on the oars. It was in any case necessary to avoid boring our oarcrews by using them for too long as mere ballast. A very few passages under oar are recorded in the literature. Those that were mentioned by ancient historians, were probably recorded because they were outstandingly memorable. The most remarkable of these was one from Athens to Mytilene, 184 sea miles, made non-stop under oar by a volunteer crew almost certainly in a selected ship, to countermand an order to execute all the men captured in that city. Thucydides's description is however baffling. One has to remember that the concept of speed as for instance miles per hour or at sea, knots, did not then exist. Distances at sea were at that time spoken of simply as 'of so many days' voyage', and times of day are rarely mentioned. However, it can be inferred from Thucydides's account that the 184 sea miles were covered in about 30 hours, at therefore an average speed of about 6 knots. If that is right, then such a ship and crew could have reached about 91/2 knots in a short sprint, say of two minutes.

At 91/2 knots the effective propulsive power required by the reconstruction is 30 kilowatts. Efficiency of rowing is not easy to measure but measurements during our sea trials indicated an efficiency of 50 to 60%. That leads to an estimate of the average power output per oarsman or woman of 300 to 350 watts. In the reconstruction we reached only 8.5 knots over a period of two minutes, calling for an effective power for the ship as a whole of only 20 kilowatts, a shortfall of about 30%.

Were the figures deduced from Thucydides wrong? Or was the modern crew not up to the standard of that of the Mytilene ship? Or is there something wrong with the reconstruction? Probably a bit of all three!

Thucydides writes that on the passage to Mytilene some oarcrew slept and others pulled, turn and turn about. That was almost certainly a good scheme but it complicates calculations. How long were the turns? Also, how smooth was the sea? And so on. The trireme reconstruction was quite new to the modern crews, and they were used only to rowing on rivers and on sliding seats. Not all were as fit as they might have been, nor were they used to the heat of Greece in August. Anachronistically, a fair proportion were women who had the advantage of fitting the ship better than the men who tended to be too tall for the trireme but suited to sliding seats, but the women were not so strong. The ship was built with oars spaced two cubits apart fore-and-aft in accordance with Vitruvius. But which cubit? There were several ancient cubits to choose from!

On that very important dimension in any oared craft, we had decided upon the so-called Attic cubit of 0.444 metre. We are now fairly convinced that that was a mistake, particularly since an unfortunately rather belated publication of a metrological stone of the right period from Salamis, which indicated a more likely cubit of 0.490 metre, 10% larger. That could have made a big difference not only in allowing longer strokes to be made, an important factor in achievable power in rowing where water is smooth enough to allow long strokes. More of the crew could have rowed, as they should, with straight arms. It would also have allowed the heads of the oarcrew in the lowest level to pass under the hull beams freeing them to make much longer strokes. That in turn, because all levels had to take the same length of stroke, would have allowed the whole crew to do the same. Such a change in the spacing of oars could well have eliminated the shortfall of 30% in sprint power and gone far to replicate the speeds probably achievable by the best ancient triremes.

We need another reconstruction! We would also, from experience with Olympias, cant the oarcrew so that the butt ends of oar handles would pass beyond the hip of the next man aft, enabling the stroke to be even longer. Oars would be immersed almost entirely forward of athwartships, as indeed they were in the later medieval galleys and are today in sport rowing craft. Our unfortunate choice of the Attic cubit in the reconstruction has a lot to answer for!

Manoeuvres in battle involving for example parts of the crew rowing and others stopping, backing down, or even pulling their oars inboard must have been ordered by hand signals because any sounds would have been drowned by general noise. The rowing master could be seen by at least the after half of the top two levels of oarcrew and the bottom level took their time from these. It is very likely that there was someone else near the mast amidships, where he could be seen by the forward half of the oarcrew, to duplicate the signals by the rowing master.

In the sea trials we measured rates of drift in the wind, and hence the wind resistance of the ship. We also carried out turning circles and a zig-zag manoeuvre to test the ship's stability in motion ahead. We have probably collected enough data on trireme manoeuvres to enable them to be simulated by computer with one of the existing programs on ship manoeuvring. If that proves possible we could go on to simulate tactics by squadrons of them and indeed whole fleets to explore some past battles and so learn more about the realities of naval warfare under oar in Classical times.

To end, may I say that the reconstruction Olympias, which is owned by the Hellenic Navy, is on public display at New Faliron, between Athens and Piraeus next to the restored 1910 heavy cruiser Averov. For anyone wishing to go further into this project, there is also a book about it entitled The Athenian Trireme, published by the Cambridge University Press.

| << Previous article | Contents | Next article >> |

| SOUE News Home |

Copyright © 2006 Society of Oxford University Engineers |

SOUE Home |